Wholesale China Zinc Parts Factory Quotes – Aluminum Alloy Die Casting Hardware Metal Door Hardware – GZ Detail:

Characteristics of Die Casting

Pressure casting, referred to as die casting, is a method of casting in which a molten alloy is poured into a press chamber, which fills the cavity of a steel mould at high speed and causes the alloy to solidify under pressure to form a cast.

The die casting method is a method of casting in which a molten alloy is poured into a press chamber, filling the cavity of a steel mould at high speed and allowing the alloy to solidify under pressure to form a cast part. The main features of die casting that distinguish it from other casting methods are high pressure and high speed.

(1 ) The metal liquid is filled in the cavity under pressure and crystallised and solidified under higher pressure, commonly 15 – -100MPa.

(2) The metal liquid fills the cavity at high speed, usually at 10 – -50 m sec, some can also exceed 80 m sec, (through the inner gate into the cavity of the line speed a inner gate

speed), so the metal liquid filling time is very short, about 0.01- 0 2 seconds (depending on the size of the casting and different) within the cavity can be filled. Die-casting machines, die-casting alloys

and die-casting moulds are the three main elements of die-casting production, the lack of – can not. The so-called die-casting process is the organic use of these three elements, so that can be stable and rhythmic

Rhythmically and efficiently produce the appearance, the internal quality of good, size in line with the drawings or agreement requirements of qualified castings, and even quality castings.

Packing and shipping

Packing details Bubble bag + export carton

Port: FOB Port Ningbo

Lead time

| Quantity (number of pieces) | 1-100 | 101-1000 | 1001-10000 | >10000 |

| Time (days) | 20 | 20 | 30 | 45 |

Payment and transportation: prepaid TT, T/T, L/C

competitive advantage

- Accept small orders

- fair price

- Deliver on time

- Timely service

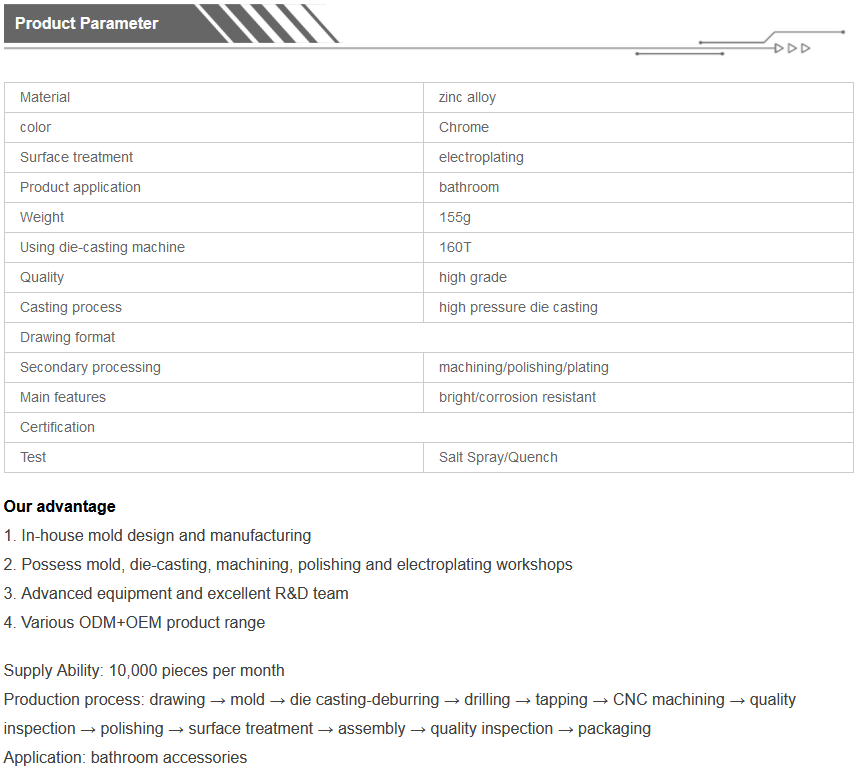

- We have more than 11 years of professional experience. As a manufacturer of bathroom accessories, we take quality, delivery time, cost, and risk as our core competitiveness, and all production lines can be effectively controlled

- The products we make can be your sample or your design

- We have a strong research and development team to solve the problem of bathroom hardware

- There are many supporting manufacturers around our factory

Product detail pictures:

Related Product Guide:

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we're much more specialist and extra hard-working and do it in cost-effective way for Wholesale China Zinc Parts Factory Quotes – Aluminum Alloy Die Casting Hardware Metal Door Hardware – GZ, The product will supply to all over the world, such as: Denmark, Bangladesh, Italy, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Thorough Info and parameters from the merchandise will probably be sent for you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

-

Wholesale China Zinc Alloy Button Manufacturers...

-

Wholesale China Zinc Alloy Die Cast Part Manufa...

-

Wholesale China Cupc Faucet Factories Pricelist...

-

Wholesale China Cupc Faucet Factories Pricelist...

-

Wholesale China Craft Aluminum Wire Manufacture...

-

Wholesale China Zinc Die-Cast Factories Priceli...