Wholesale China Zinc Handicrafts Manufacturers Suppliers – Zinc Die Casting Mould of Architectural Hardwares – GZ Detail:

Zinc alloy die-casting factory specializing in zinc alloy die-casting processing, zinc alloy die-casting products, 20 years of experience in zinc alloy mold design and development! 20 years of experience in precision die-casting! Focus on die-casting, focus on quality! Choose Guanzhi is your guarantee of quality and delivery~!

1. Welcome to come to the picture to sample processing custom-made, equipped with from product design to hit the plate, mold, die-casting, polishing, plating, packaging to finished products shipped

2. Mainly engaged in zinc alloy die-casting, lighting accessories, small accessories, electronic components hardware, precision accessories all over the world.

3. Our factory has 88T and 128T zinc alloy die-casting machine can undertake the product die-casting to the finished product shipment.

4.20 years of experience in precision production and 20 years of experience in precision mould development

5, polishing plating without pitting, no water lines, no blistering, no sand holes; oxidizable, high precision (accurate to +-0.02)

6. Precision zinc alloy products can be molded in 5 days at the earliest

7. Management purpose: we do not only do the product, but more importantly, a responsibility.

8. 20 years of experience in precision die-casting mould design and development is your guarantee of quality

Product parameter

| Material | zinc alloy |

| color | Chrome |

| Surface treatment | electroplating |

| Product application | bathroom |

| Weight | 124g |

| Using die-casting machine | 160T |

| Quality | high grade |

| Casting process | high pressure die casting |

| Drawing format | |

| Secondary processing | machining/polishing/plating |

| Main features | bright/corrosion resistant |

| Certification | |

| Test | Salt Spray/Quench |

Our advantage

1. In-house mold design and manufacturing

2. Possess mold, die-casting, machining, polishing and electroplating workshops

3. Advanced equipment and excellent R&D team

4. Various ODM+OEM product range

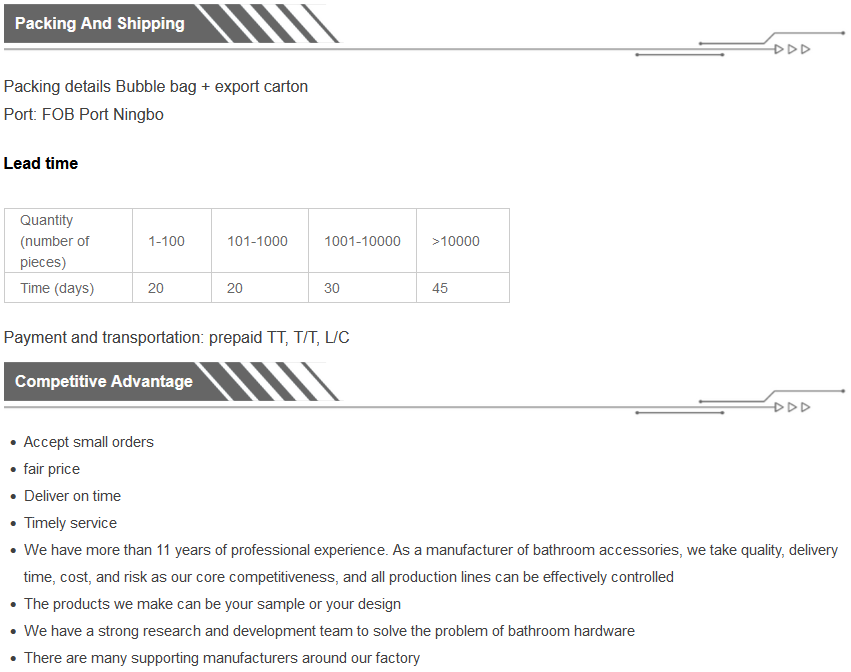

Supply Ability: 10,000 pieces per month

Production process: drawing → mold → die casting-deburring → drilling → tapping → CNC machining → quality inspection → polishing → surface treatment → assembly → quality inspection → packaging

Application: bathroom accessories

Product detail pictures:

Related Product Guide:

Our pursuit and company intention is usually to "Always fulfill our purchaser requirements". We go on to acquire and layout excellent high quality products for both our previous and new consumers and realize a win-win prospect for our customers too as us for Wholesale China Zinc Handicrafts Manufacturers Suppliers – Zinc Die Casting Mould of Architectural Hardwares – GZ, The product will supply to all over the world, such as: Belgium, Liberia, Niger, Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

Wholesale China Custom Faucet Factory Quotes &#...

-

Wholesale China Custom Used Aluminum Alloy Whee...

-

Wholesale China Zinc Alloy Casting Factories Pr...

-

Wholesale China Aluminum Casting Alloys Manufac...

-

Wholesale China Aluminum Die Casting Factories ...

-

Wholesale China Aluminum Bookmark Manufacturers...