Wholesale China Zinc Die Casting Parts Manufacturers Suppliers – Custom die casting metal aluminium zinc casting forging die casting moulds die – GZ Detail:

Product Introduction

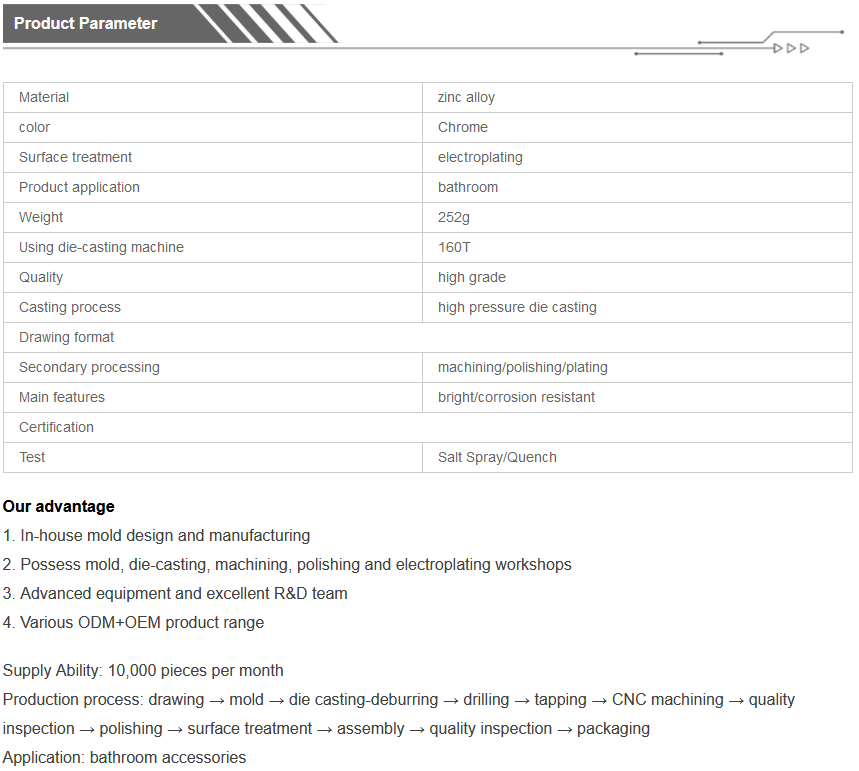

1. Production process

The surface of high-quality door hardware is smooth, flat and free of air holes, burrs and blemishes. This is due to the large forging presses used to forge the hardware, the high mechanical strength of which makes the density of the material extremely high, and the dozens of precision machine tools to polish and grind the product to a mirror-like shine.

In contrast, inferior door hardware products are produced using small die-casting machines and rudimentary lathes, and generally have a loose structure.

2. Plating process

The plating layer of high-quality door hardware products is often bright and even, with a natural colour and good density, and the plating layer is visually thick. Poor quality door hardware products have dull plating, thin plating and are prone to rust, wear and tear, flaking and blistering in the short term.

Hardware with a strong sense of design brings a pleasant feeling not only visually, but also expresses a deeper level of taste in the home. You can choose from the following three points.

1, style coordination: the door lock shape style to match the home decoration style; advice: let the designer accompanied by reference or take the designer’s proposed drawings to the market, so that it is easier to grasp the style problem.

2, colour matching: the colour of the door lock should be coordinated with the door and interior tones. Suggestion: listen to the designer’s advice.

3, grade matching: a good horse with a good saddle, the grade of the door lock to match the grade of the decoration; in the middle and high grade decoration, only copper locks can match.

Packing and shipping

Packing details Bubble bag + export carton

Port: FOB Port Ningbo

Lead time

| Quantity (number of pieces) | 1-100 | 101-1000 | 1001-10000 | >10000 |

| Time (days) | 20 | 20 | 30 | 45 |

Payment and transportation: prepaid TT, T/T, L/C

competitive advantage

- Accept small orders

- fair price

- Deliver on time

- Timely service

- We have more than 11 years of professional experience. As a manufacturer of bathroom accessories, we take quality, delivery time, cost, and risk as our core competitiveness, and all production lines can be effectively controlled

- The products we make can be your sample or your design

- We have a strong research and development team to solve the problem of bathroom hardware

- There are many supporting manufacturers around our factory

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of Wholesale China Zinc Die Casting Parts Manufacturers Suppliers – Custom die casting metal aluminium zinc casting forging die casting moulds die – GZ, The product will supply to all over the world, such as: Israel, St. Petersburg, Jordan, We look forward to hearing from you, whether you are a returning customer or a new one. We hope you will find what you are looking for here, if not, please contact us immediately. We pride ourselves on top notch customer service and response. Thank you for your business and support!

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

-

Wholesale China Zinc Alloy Crafts Factory Quote...

-

Wholesale China Zinc Alloy Trophy Factory Quote...

-

Wholesale China Zinc Alloy Die Casting Factorie...

-

Wholesale China Aluminum Crafts Manufacturers S...

-

Wholesale China Aluminum Foil Badge Factories P...

-

Wholesale China Zinc Alloy Plating Manufacturer...