Wholesale China Zinc Die Casting Factories Pricelist – Aluminum Die Casting Manufacturing Process – GZ Detail:

The company produces CNC machining parts, CNC turning parts, stamping parts, sheet metal, sheet metal chassis, hinges, automotive hardware fittings, medical hardware fittings, health care hardware fittings, furniture hardware fittings, etc.. The company enjoys a high status among hardware trade merchants and furniture supplies, and has established long-term and stable cooperative relations with many wholesalers and agents.

Precision metal stamping, a variety of materials to choose from, precision stamping custom processing

Materials

Genuine 304 stainless steel is used to extend the life of the product.

Appearance

Designed by a senior designer. Details reflect taste! This is also true of industrial product design.

Corners

The corners are designed to be a delight to the eye.

Tactility

Mirror-like smoothness that you can’t help but love

Products from Guanzhi Hardware

We use the finest raw materials to produce products that are beautifully detailed, smooth and rounded to the touch and have a long service life.

Quality Control Process

The whole process is controlled and managed in 16 steps to ensure that the production plant, environment and production equipment meet all requirements. All production processes are carried out in accordance with the approved process plan, checked and upgraded based on experience and proven to meet quality requirements and industry standard production specifications.

Product parameter

| Material | zinc alloy |

| color | Chrome |

| Surface treatment | electroplating |

| Product application | bathroom |

| Weight | 358g |

| Using die-casting machine | 160T |

| Quality | high grade |

| Casting process | high pressure die casting |

| Drawing format | |

| Secondary processing | machining/polishing/plating |

| Main features | bright/corrosion resistant |

| Certification | |

| Test | Salt Spray/Quench |

Our advantage

1. In-house mold design and manufacturing

2. Possess mold, die-casting, machining, polishing and electroplating workshops

3. Advanced equipment and excellent R&D team

4. Various ODM+OEM product range

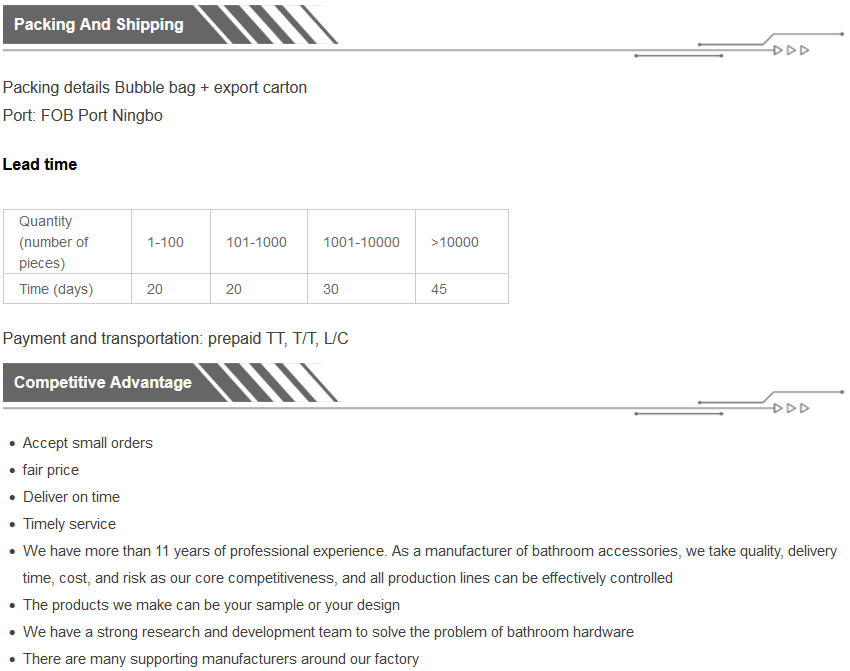

Supply Ability: 10,000 pieces per month

Production process: drawing → mold → die casting-deburring → drilling → tapping → CNC machining → quality inspection → polishing → surface treatment → assembly → quality inspection → packaging

Application: bathroom accessories

Product detail pictures:

Related Product Guide:

We regularly perform our spirit of ''Innovation bringing progress, Highly-quality making certain subsistence, Administration marketing benefit, Credit score attracting customers for Wholesale China Zinc Die Casting Factories Pricelist – Aluminum Die Casting Manufacturing Process – GZ, The product will supply to all over the world, such as: Mauritania, Barbados, Armenia, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

-

Wholesale China Aluminum Foil Craft Factories P...

-

Wholesale China Zinc Alloy Badges Factory Quote...

-

Wholesale China Zinc Parts Manufacturers Suppli...

-

Wholesale China Aluminum Air Vent Cap Manufactu...

-

Wholesale China Shower Faucet Factories Priceli...

-

Wholesale China Aluminum Foil Craft Factory Quo...