Wholesale China Zinc Aluminum Die Casting Parts Factory Quotes – Aluminum die casting manufacturing crafts – GZ Detail:

Product parameter

| Material | zinc alloy |

| color | Chrome |

| Surface treatment | electroplating |

| Product application | bathroom |

| Weight | 2400g |

| Using die-casting machine | 400T |

| Quality | high grade |

| Casting process | high pressure die casting |

| Drawing format | |

| Secondary processing | machining/polishing/plating |

| Main features | bright/corrosion resistant |

| Certification | |

| Test | Salt Spray/Quench |

Our advantage

1. In-house mold design and manufacturing

2. Possess mold, die-casting, machining, polishing and electroplating workshops

3. Advanced equipment and excellent R&D team

4. Various ODM+OEM product range

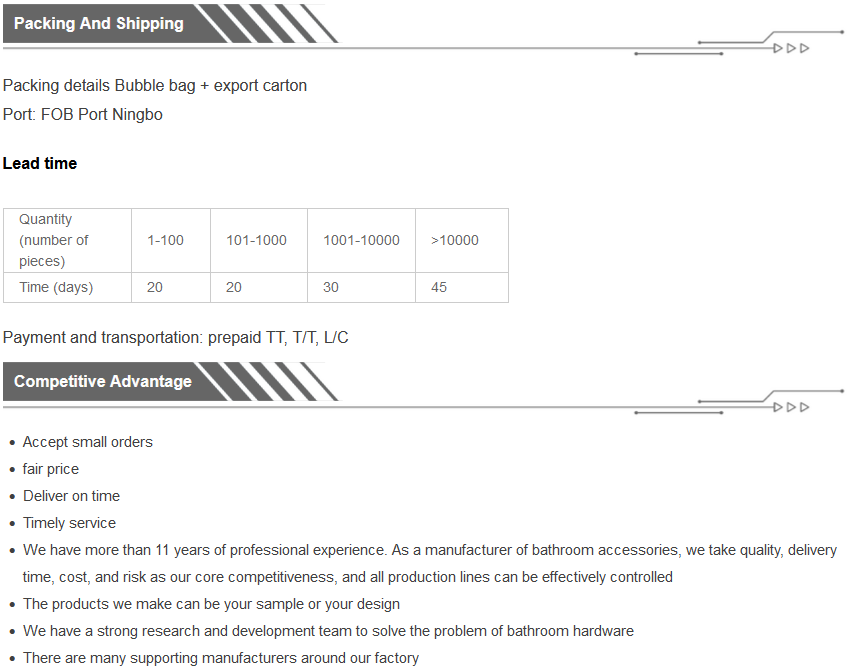

Supply Ability: 10,000 pieces per month

Production process: drawing → mold → die casting-deburring → drilling → tapping → CNC machining → quality inspection → polishing → surface treatment → assembly → quality inspection → packaging

Application: bathroom accessories

Product Introduction

About zinc die castings

Zinc alloy die castings are pressure cast parts, which are cast using a pressure casting machine fitted with a casting mould.

The zinc or zinc alloy heated to a liquid state is poured into the inlet of the die-casting machine and die-cast by the die-casting machine to produce a zinc or zinc alloy part of the shape and size restricted by the mould.

Features of zinc die casting

The main characteristics of zinc alloy die casting are, the melting point of zinc alloy is low, the temperature reaches four hundred degrees when the zinc alloy melts, this is better in zinc alloy die casting for forming. Zinc alloy does not absorb iron during the melting and die-casting process, and zinc alloy casting performance is good, in the die-casting process can be put a lot of complex shape of precision parts, the surface of the castings after the completion of the die-casting looks very smooth. At the same time, the specific gravity of zinc alloys is relatively high.

Product detail pictures:

Related Product Guide:

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Wholesale China Zinc Aluminum Die Casting Parts Factory Quotes – Aluminum die casting manufacturing crafts – GZ, The product will supply to all over the world, such as: Malta, Amman, Italy, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

-

Wholesale China Aluminum Trophy Factory Quotes ...

-

Wholesale China Aluminum Casting Factories Pric...

-

Wholesale China Zinc Alloy Sculpture Manufactur...

-

Wholesale China Aluminum Die Casting Factories ...

-

Wholesale China Zinc Die Casting Finishing Fact...

-

Wholesale China Zinc Alloy Products Factory Quo...