Wholesale China Zinc Aluminum Die Casting Parts Factories Pricelist – Aluminum Die Casting Manufacturing Process – GZ Detail:

The company produces CNC machining parts, CNC turning parts, stamping parts, sheet metal, sheet metal chassis, hinges, automotive hardware fittings, medical hardware fittings, health care hardware fittings, furniture hardware fittings, etc.. The company enjoys a high status among hardware trade merchants and furniture supplies, and has established long-term and stable cooperative relations with many wholesalers and agents.

Precision metal stamping, a variety of materials to choose from, precision stamping custom processing

Materials

Genuine 304 stainless steel is used to extend the life of the product.

Appearance

Designed by a senior designer. Details reflect taste! This is also true of industrial product design.

Corners

The corners are designed to be a delight to the eye.

Tactility

Mirror-like smoothness that you can’t help but love

Products from Guanzhi Hardware

We use the finest raw materials to produce products that are beautifully detailed, smooth and rounded to the touch and have a long service life.

Quality Control Process

The whole process is controlled and managed in 16 steps to ensure that the production plant, environment and production equipment meet all requirements. All production processes are carried out in accordance with the approved process plan, checked and upgraded based on experience and proven to meet quality requirements and industry standard production specifications.

Product parameter

| Material | zinc alloy |

| color | Chrome |

| Surface treatment | electroplating |

| Product application | bathroom |

| Weight | 358g |

| Using die-casting machine | 160T |

| Quality | high grade |

| Casting process | high pressure die casting |

| Drawing format | |

| Secondary processing | machining/polishing/plating |

| Main features | bright/corrosion resistant |

| Certification | |

| Test | Salt Spray/Quench |

Our advantage

1. In-house mold design and manufacturing

2. Possess mold, die-casting, machining, polishing and electroplating workshops

3. Advanced equipment and excellent R&D team

4. Various ODM+OEM product range

Supply Ability: 10,000 pieces per month

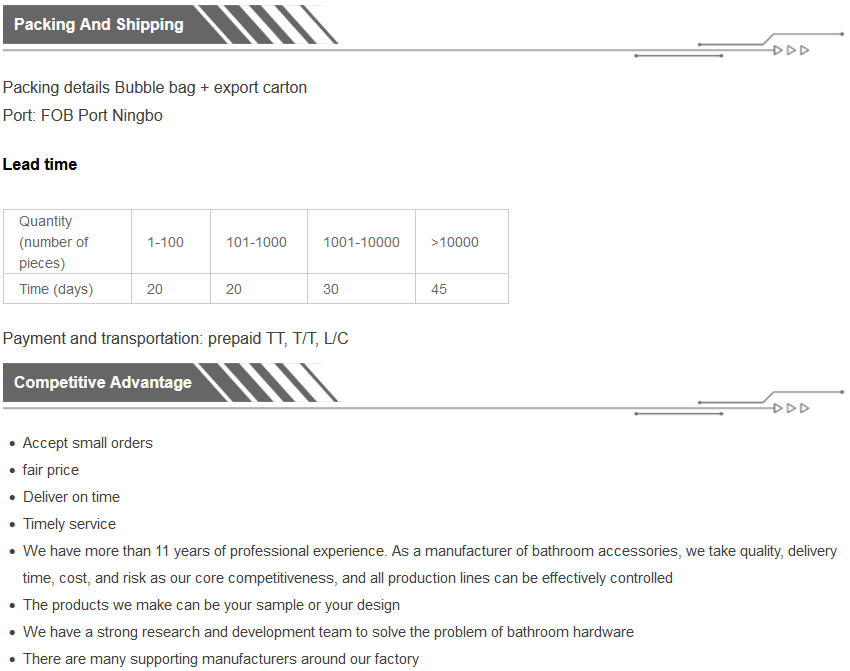

Production process: drawing → mold → die casting-deburring → drilling → tapping → CNC machining → quality inspection → polishing → surface treatment → assembly → quality inspection → packaging

Application: bathroom accessories

Product detail pictures:

Related Product Guide:

Every single member from our higher effectiveness product sales staff values customers' requires and organization communication for Wholesale China Zinc Aluminum Die Casting Parts Factories Pricelist – Aluminum Die Casting Manufacturing Process – GZ, The product will supply to all over the world, such as: Greece, Uzbekistan, Denver, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!

-

Wholesale China Aluminum Casting Cylinder Head ...

-

Wholesale China Aluminum Trophy Manufacturers S...

-

Wholesale China Zinc Alloy Sculpture Factories ...

-

Wholesale China Aluminum Fish Sculpture Factori...

-

Wholesale China Aluminum Cylinder Cover Factori...

-

Wholesale China Zinc Alloy Trophy Factories Pri...