Wholesale China Zinc Alloy Jewelry Box Factory Quotes – Zinc Die Casting Mould of Architectural Hardwares – GZ Detail:

Product Description

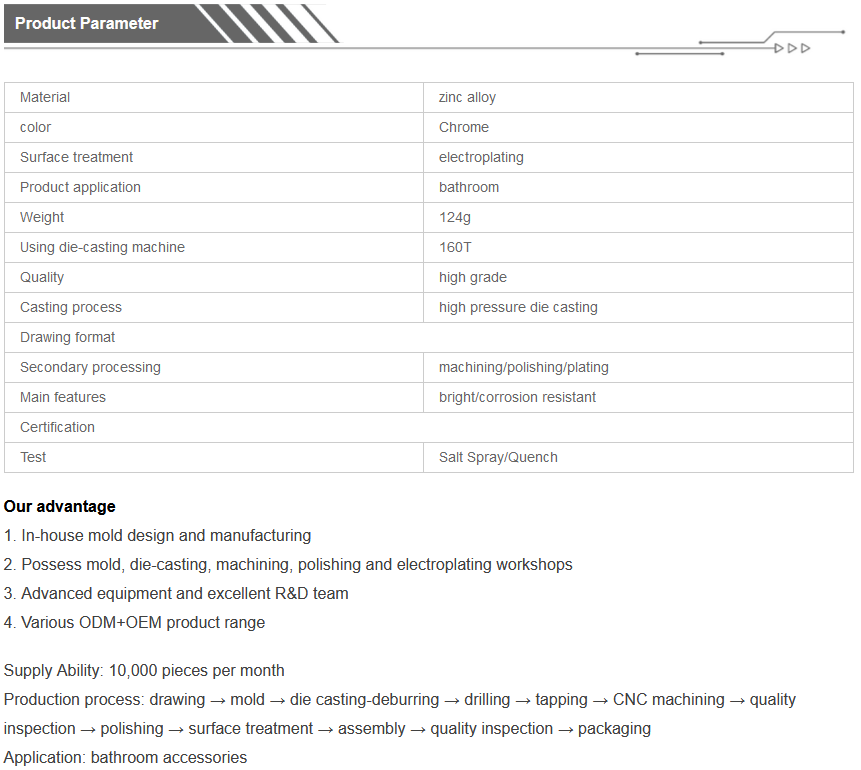

● Product material: Zinc alloy

● Surface treatment: polishing, electrophoresis or oil spraying Electroplating

● Mould material: mould steel

● Product features: The surface can be ordered in many colours according to customer’s requirements, and many specifications can be ordered according to customer’s requirements

● Product advantage: The surface can be made without sand holes. The surface is smooth and high-grade.

R&D Process

The customer provides samples or drawings, material requirements, precision tolerances, surface treatment and special requirements.

Our customer service receives the drawings and gives the project engineering department the first time to evaluate and quote, the structure and price of the product drawings are confirmed.

After the product structure and price are confirmed, a contract will be signed. Then our mould department will carry out mould design and trial moulding of small batch samples.

After the customer confirms again, the product is put into mass production.

Zinc alloy die-casting factory specializing in zinc alloy die-casting processing, zinc alloy die-casting products, 20 years of experience in zinc alloy mold design and development! 20 years of experience in precision die-casting! Focus on die-casting, focus on quality! Choose Guanzhi is your guarantee of quality and delivery~!

Packing and shipping

Packing details Bubble bag + export carton

Port: FOB Port Ningbo

Lead time

| Quantity (number of pieces) | 1-100 | 101-1000 | 1001-10000 | >10000 |

| Time (days) | 20 | 20 | 30 | 45 |

Payment and transportation: prepaid TT, T/T, L/C

competitive advantage

- Accept small orders

- fair price

- Deliver on time

- Timely service

- We have more than 11 years of professional experience. As a manufacturer of bathroom accessories, we take quality, delivery time, cost, and risk as our core competitiveness, and all production lines can be effectively controlled

- The products we make can be your sample or your design

- We have a strong research and development team to solve the problem of bathroom hardware

- There are many supporting manufacturers around our factory

Company strength

●The company has 20 years of experience in precision equipment processing and casting, and a complete production process.

●Engineers have senior professional technology and production experience.

●An integrated enterprise of industry and trade, providing customers with sharply competitive products.

Service

Drawing:we can translate your original drawing, offer best suggestion on design.

Quality: we have full set quality control system to guarantee the best quality.

FAQ

Q1: What information should I give to you for inquiry?

A1:lf you have drawings or samples,please feel free to send us,and tell us your special

requirements such as material ,tolerance,surface treatments and the amount you need,etc.

Q2: Do you provide sample?

A1.Yes, we can provide you sample before mass order.

Q3: What kind of production service do you provide?

A3:We provide mold making, die casting, CNC machining, stamping, plastic injection,

assembly, and surface treatment,etc.

Q4:Is it safe to send my drawings to you?

A4:Yes, We are pleased to sign NDA with you before you send the drawings if you wish.

Q5:Delivery time?

A5:Normally 25-40days depends on the order specific items and quantities.

Q6:How do I know the status of my project without going to the factory?

A6:you can always ask our sales staff to provide you with photos and videos.

Q7. How about the packing?

A7:Normally we pack goods according to customers’ requirement.

For reference. wrapping paper, carton box, wooden case, pallet.

Q8:What is your payment term?

A8:Mold: 50% prepaid, balance after sample approval.

Goods: 50% prepaid, balance T/T before shipment.

Q9: How to deal with the parts received in poor quality?

A9:This has never been occurred right now ,as we treat the quality as our key of

development. Quality and service is everything for US.

Product detail pictures:

Related Product Guide:

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for Wholesale China Zinc Alloy Jewelry Box Factory Quotes – Zinc Die Casting Mould of Architectural Hardwares – GZ, The product will supply to all over the world, such as: Eindhoven, Pretoria, Vietnam, We've customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don't hesitate to contact us.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

-

Wholesale China Aluminum Cans Candle Factory Qu...

-

Wholesale China Aluminum Sheet Trophy Factories...

-

Wholesale China Zinc Alloy Plating Manufacturer...

-

Wholesale China Art Aluminum Wire Factories Pri...

-

Wholesale China Aluminum Die Casting Auto Parts...

-

Wholesale China Zinc Alloy Plating Factories Pr...