Wholesale China Zinc Alloy Die Cast Part Factories Pricelist – Zinc Die Casting Mould of Architectural Hardwares – GZ Detail:

Zinc alloy die-casting factory specializing in zinc alloy die-casting processing, zinc alloy die-casting products, 20 years of experience in zinc alloy mold design and development! 20 years of experience in precision die-casting! Focus on die-casting, focus on quality! Choose Guanzhi is your guarantee of quality and delivery~!

1. Welcome to come to the picture to sample processing custom-made, equipped with from product design to hit the plate, mold, die-casting, polishing, plating, packaging to finished products shipped

2. Mainly engaged in zinc alloy die-casting, lighting accessories, small accessories, electronic components hardware, precision accessories all over the world.

3. Our factory has 88T and 128T zinc alloy die-casting machine can undertake the product die-casting to the finished product shipment.

4.20 years of experience in precision production and 20 years of experience in precision mould development

5, polishing plating without pitting, no water lines, no blistering, no sand holes; oxidizable, high precision (accurate to +-0.02)

6. Precision zinc alloy products can be molded in 5 days at the earliest

7. Management purpose: we do not only do the product, but more importantly, a responsibility.

8. 20 years of experience in precision die-casting mould design and development is your guarantee of quality

Product parameter

| Material | zinc alloy |

| color | Chrome |

| Surface treatment | electroplating |

| Product application | bathroom |

| Weight | 124g |

| Using die-casting machine | 160T |

| Quality | high grade |

| Casting process | high pressure die casting |

| Drawing format | |

| Secondary processing | machining/polishing/plating |

| Main features | bright/corrosion resistant |

| Certification | |

| Test | Salt Spray/Quench |

Our advantage

1. In-house mold design and manufacturing

2. Possess mold, die-casting, machining, polishing and electroplating workshops

3. Advanced equipment and excellent R&D team

4. Various ODM+OEM product range

Supply Ability: 10,000 pieces per month

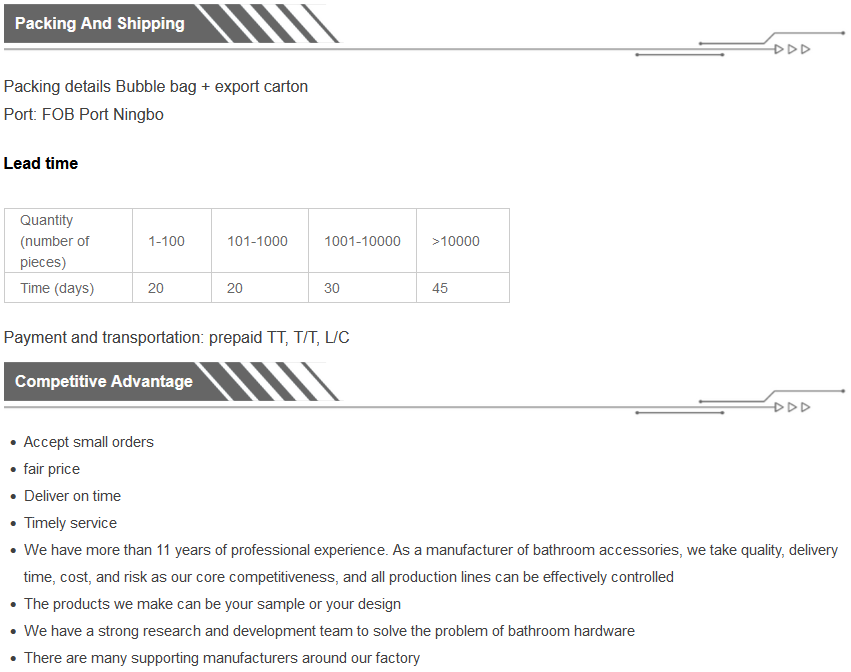

Production process: drawing → mold → die casting-deburring → drilling → tapping → CNC machining → quality inspection → polishing → surface treatment → assembly → quality inspection → packaging

Application: bathroom accessories

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with Wholesale China Zinc Alloy Die Cast Part Factories Pricelist – Zinc Die Casting Mould of Architectural Hardwares – GZ, The product will supply to all over the world, such as: Slovak Republic, Bangladesh, Manila, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

-

Wholesale China Zinc Die Casting Parts Factory ...

-

Wholesale China Aluminum Sheet Trophy Manufactu...

-

Wholesale China Medal Zinc Alloy Factory Quotes...

-

Wholesale China Craft Aluminum Wire Manufacture...

-

Wholesale China Aluminum Tokens Manufacturers S...

-

Wholesale China Zinc Alloy Brake Lining Factori...