Wholesale China Style Zinc Electroplating Factories Pricelist – Customized Hardware Stamping Parts Aluminum Die Casting – GZ Detail:

Product parameter

| Material | zinc alloy |

| color | Chrome |

| Surface treatment | electroplating |

| Product application | bathroom |

| Weight | 132g |

| Using die-casting machine | 160T |

| Quality | high grade |

| Casting process | high pressure die casting |

| Drawing format | |

| Secondary processing | machining/polishing/plating |

| Main features | bright/corrosion resistant |

| Certification | |

| Test | Salt Spray/Quench |

Advantages

Advantages of our hardware casting products

1.20 years’ experience in the design and development of precision zinc alloy die-casting and aluminium alloy die-casting moulds, with strong technical strength in precision die-casting and precision die-casting production capacity

2.We have a number of high quality engineers, technical and management personnel, and can design and develop various kinds of mobile phone bezel

We can design and develop various kinds of mobile phone bezels according to customers’ requirements, with exquisite technology and multiple colours on the surface.

3. Advanced equipment, scientific process management production, 24-hour fully automatic mechanical production operation, independent mould room (spark machine, computer gong, milling machine, precision grinding machine) polishing room, vibration grinding machine, sand blasting room, sand room wire drawing machine, batch front line

4. With unique core technology, quality is more secure, high precision alloy die casting, can control tolerance + -0.02, can control no sand holes, no water plating no blistering, no pitting, no rust, no oxidation die casting finished products uniform density, the product is not easy to break, deformation, stable quality, shipping layers of testing, can be sandblasted oxidation of various colours

5.Quality service. The whole process is worry-free

Supply Ability: 10,000 pieces per month

Production process: drawing → mold → die casting-deburring → drilling → tapping → CNC machining → quality inspection → polishing → surface treatment → assembly → quality inspection → packaging

Application: bathroom accessories

Product detail pictures:

Related Product Guide:

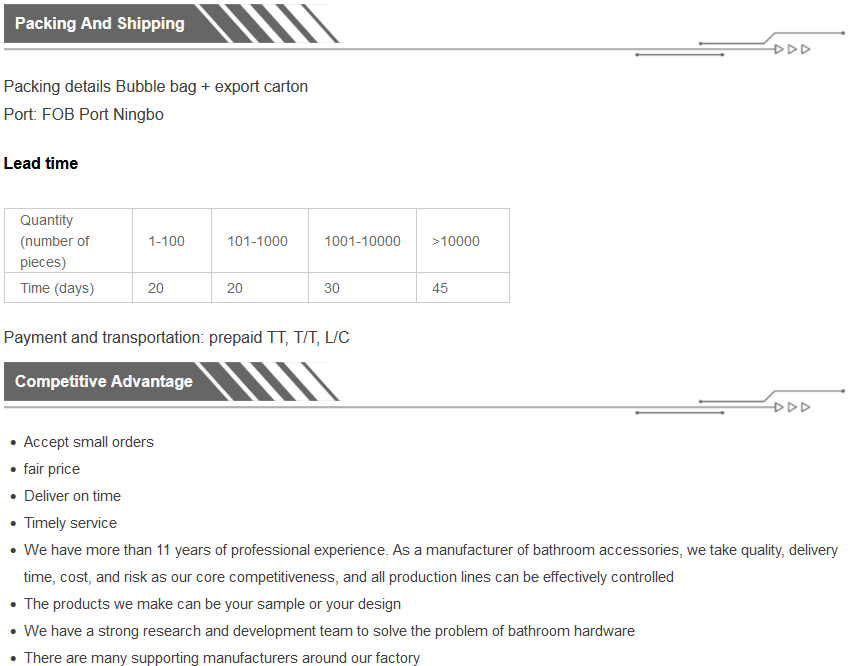

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for Wholesale China Style Zinc Electroplating Factories Pricelist – Customized Hardware Stamping Parts Aluminum Die Casting – GZ, The product will supply to all over the world, such as: Lisbon, Bolivia, Bogota, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

-

Wholesale China Touchless Kitchen Faucet Factor...

-

Wholesale China Aluminum Circles For Crafts Fac...

-

Wholesale China Zinc Alloy Auto Parts Manufactu...

-

Wholesale China Plastic Faucet Factory Quotes &...

-

Wholesale China Desk Mounted Kitchen Faucet Fac...

-

Wholesale China Custom Used Aluminum Alloy Whee...