Product parameter

| Material | zinc alloy |

| color | Chrome |

| Surface treatment | electroplating |

| Product application | bathroom |

| Weight | 153g |

| Using die-casting machine | 160T |

| Quality | high grade |

| Casting process | high pressure die casting |

| Drawing format | |

| Secondary processing | machining/polishing/plating |

| Main features | bright/corrosion resistant |

| Certification | |

| Test | Salt Spray/Quench |

Our advantage

1. In-house mold design and manufacturing

2. Possess mold, die-casting, machining, polishing and electroplating workshops

3. Advanced equipment and excellent R&D team

4. Various ODM+OEM product range

Supply Ability: 10,000 pieces per month

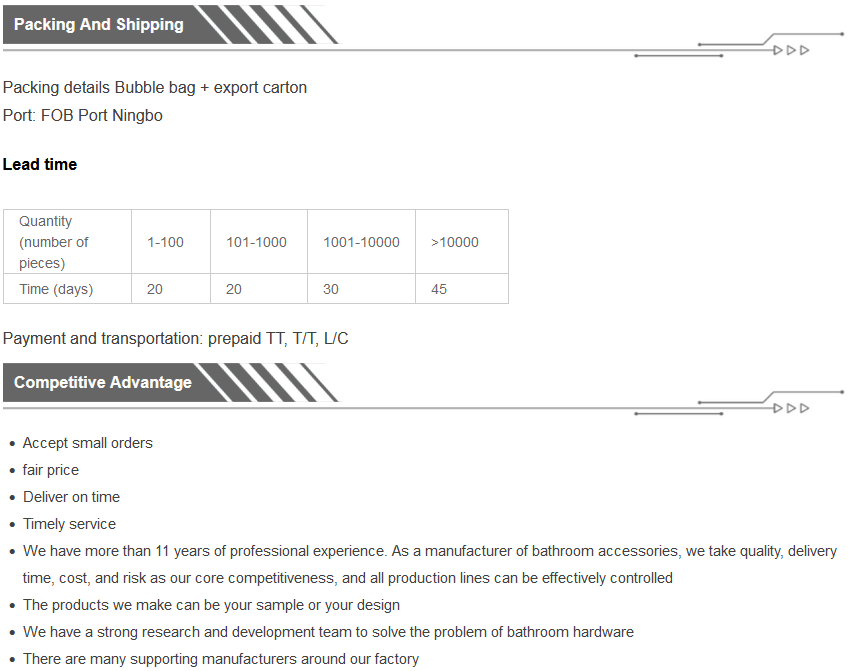

Production process: drawing → mold → die casting-deburring → drilling → tapping → CNC machining → quality inspection → polishing → surface treatment → assembly → quality inspection → packaging

Application: bathroom accessories

Performance: The overall aesthetics of the Guanzhi brand pull handle and the surface finish greatly enhances the overall beauty of the handle. The humanized design of the surface of the handle, with smooth lines, enhances the feel of the handle and makes it more comfortable to hold. The handle is easy to install, easy to use, heat resistant, high load capacity, easy to use, environmentally safe, solid, vibration resistant, strong fastening, can be repeatedly closed and opened for use.

Uses: medical boxes, aviation boxes, heavy duty boxes and bags, fire boxes, boots, import and export packing boxes, wooden boxes, machinery, instruments, ships, aviation equipment, monitoring equipment, various high-end equipment.

Installation method: according to the physical hole spacing specifications of the product, set the size, and then operate with rivets, screws, spot welding, etc.

Storage method: Store in a dry location, do not stack in a damp, cold place to avoid rusting or oxidation of the product.

Die Casting Tips

Pressure is a fundamental feature of the die casting process, the filling flow and compaction of the metal fluid are done under the action of pressure. The pressure is divided into dynamic pressure and pressurised pressure. The function of the dynamic press force is to overcome all kinds of resistance and to ensure that the liquid reaches a certain speed when filling the mould. The function of the pressurised injection force is to compact the die casting at the end of the filling, to increase the density of the die casting and to give it a clear profile. The press force is applied to the metal fluid by means of a press punch.